Ferrite magnets,also known as ceramic magnets are a type of permanent magnet and are made of the chemical compound ferrite, which consists of ceramic materials and iron oxide(Fe2O3),the chemical composition is SrO-6(Fe2O3).Ferrite compounds are extremely low cost, being made of mostly iron oxide, and have excellent corrosion resistance.

Ferrites can be divided into two types based on their resistance to be demagnetized (magnetic coercivity).

Hard ferrites have high coercivity, so they are difficult to demagnetize. They are used to make permanent magnets for applications such as refrigerator magnets, loudspeakers,and small electric motors.

Soft ferrites have low coercivity, so they easily change their magnetization and act as conductors of magnetic fields. They are used in the electronic industry to make efficient magnetic cores called ferrite cores for high-frequency inductors, transformers and antennas,and in various microwave components.

Ferrite cores are used in electronic inductors, transformers, and electromagnets where the high electrical resistance of the ferrite leads to very low eddy current losses.

Most common audio magnets, including those used in loudspeakers and electromagnetic instrument pickups, are ferrite magnets.

Ferrite magnets have largely displaced the more expensive Alnico magnets in many applications. In particular, for hard hexaferrites , the most common uses are still as permanent magnets in refrigerator seal gaskets, microphones small motors for cordless appliances and in automobile applications.

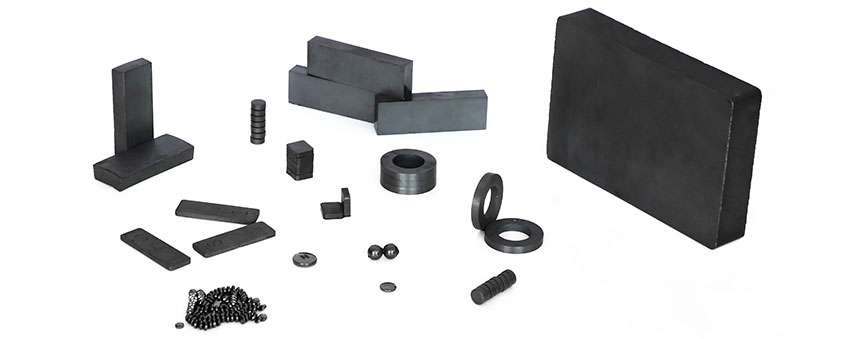

We provide Ferrite Magnets in various shapes such as round, block, ring, arc, special shape in various sizes according to customers’ requirements.

We can also custom manufacture ceramic magnets to fit your exact specifications, just contact us today, and we’ll work with you to determine the most economical solution for your project.

| Grade | Remanence Flux Density |

Coercive | Max Energy Density |

Temp. Coefficient |

Operating Temp. |

||||||

| Br | Hcb | Hcl | (BH)max | TK(Br) %/k |

TK(Hcj) %/k |

Tw max | |||||

| kGs | ml | kOe | kA/m | kOe | kA/m | MGOe | KJ/m³ | C | |||

| Y10T | 2.00-2.18 | 200-218 | 1.57-1.82 | 125-145 | 2.64-3.14 | 210-250 | 0.8-1.0 | 6.5-8.0 | -0.2 | 0.3 | 250 |

| Y25 | 3.60-3.70 | 360-370 | 1.70-1.88 | 135-150 | 1.76-2.14 | 140-170 | 2.8-3.2 | 22.5-25.3 | -0.2 | 0.3 | 250 |

| Y30 | 3.80-3.90 | 380-390 | 2.40-2.64 | 191-210 | 2.50-2.51 | 199-220 | 3.4-3.7 | 27.0-30.0 | -0.2 | 0.3 | 250 |

| Y33 | 4.00-4.10 | 400-410 | 2.20-2.45 | 175-195 | 2.26-2.51 | 180-200 | 3.8-4.0 | 30.0-31.5 | -0.2 | 0.3 | 250 |

| Y35 | 4.10-4.20 | 410-420 | 2.77-2.95 | 220-235 | 2.83-3.01 | 225-240 | 4.0-4.2 | 31.5-33.0 | -0.2 | 0.3 | 250 |

| Y30BH | 3.80-3.90 | 380-390 | 2.80-2.95 | 223-235 | 2.90-3.08 | 231-245 | 3.4-3.7 | 27.0-30.0 | -0.2 | 0.3 | 250 |

| Y33BH | 4.00-4.10 | 400-410 | 3.62-3.77 | 288-300 | 3.51-3.60 | 280-287 | 3.8-4.0 | 30.4-31.5 | -0.2 | 0.3 | 250 |